Dunnage Air Bags for Cargo Securement

An Economical and Efficient Way to Protect Your Cargo while Shipping Your Products to Customers

It is hard work to create a Quality Product at Competitive Price in most industries. It is harder to deal with a complaint on your products from damage in shipment. Load Securement prevents complaints from your customers and saves your bottom line. Dunnage Air Bags are cheap, easy to install, and give peace of mind that your product will ship to the customer the way it was meant to.

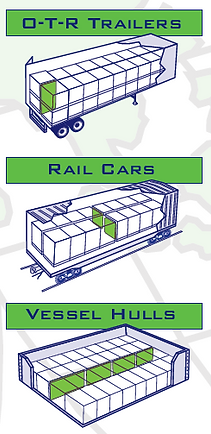

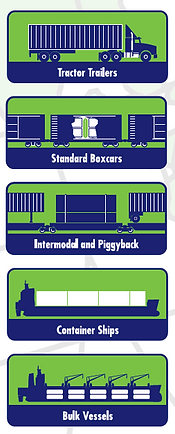

Dunnage Air Bags Can Be Used in all these Modes of Transportation

By Truck

By Intermodal Containers

(Road/Rail/Ship)

By Heavy and Light Rail Car Applications

By Installing in Hulls of Ships

What is a Dunnage Air Bag?

There are a lot of ways to prevent your cargo from moving around while in transit. They range from expensive and a lot of labor time (such as strapping or building bulk heads) to economical and fast to install (like dunnage air bags).

Dunnage Air Bags are light bags containing a internal bladder and outer shell (paper or polywoven) in which air is filled into the bag and pushes the products against the walls of the trailer/container or rail car. This creates friction in which will prevent the swaying and moving while the cargo is in movement.

Air Bags only take a few moments to install and fill to secure the cargo. Once the bags are properly positioned correctly, filled, and checked, the cargo is ready to go.

For the customer to discharge, simply depress the valve and release the air until the bag can be removed.

Why do you need to secure your cargo while shipping products from your warehouse to your customers?

Imagine you are flying on a plane while sitting in your seat. During take off, you feel your body getting pressed into your seat as you are accelerating. During turbulence, you feel the upwards, downwards and side to side motion. Last, during landing, you are pulled forward in your seat as the plane is decelerating as it lands on the runway. This may seem extreme, but your cargo is doing the same while in shipment.

If you don't secure your cargo, your cargo will move around in whatever means it is packed in. A truck will accelerate, decelerate, and tilt as turning. A rail shipment will have the same motions. Last sea shipments, will have all of this including the rocking while in heavy seas.

The pictures to the right show the forces being applied while your cargo in transit. By preventing/securing your cargo, you just saved your cargo from damage and saved the time and expense of complaints.

What makes Bulk-Pack different than its Competition?

There are good manufacturers of dunnage air bags. What separates us is that we have taken advantage of our Mexico plant to provide a higher level of service and quality.

We have the ability to make bags faster, replenish stock, make custom sizes within weeks vs. our competitors that import from abroad. We are the manufacturer thus we have 100% control of our products vs. distributors that import from overseas.

Our focus isn't to be the biggest manufacturer, it is to be the best servicing manufacturer with a great quality record. Our Sales Team is dedicated to find solutions for our customers whether it is to save you money OR make sure you are utilizing the right bag for the right cargo.

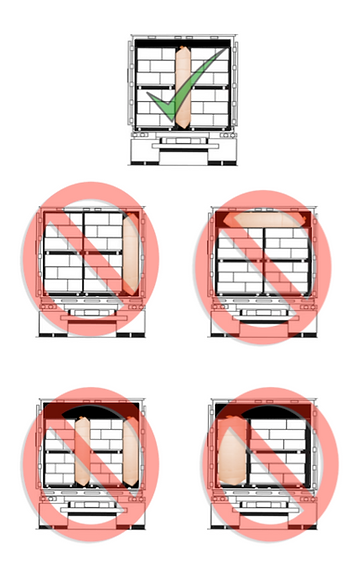

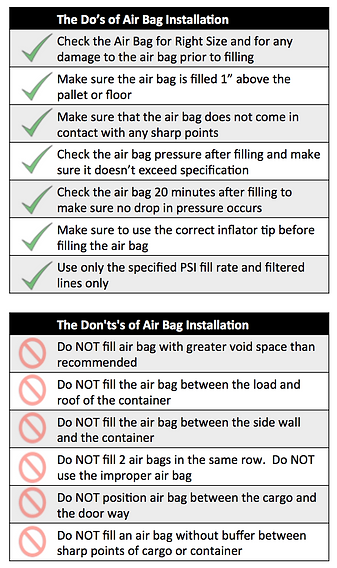

The Do's and Don't's of Dunnage Air Bag Installation

As in anything, if dunnage air bags are not properly filled or handled, it is doomed to fail. Bulk-Pack, Inc. is happy to teach you how to properly store, handle, install, check and deflate air bags. Below are the basics of handling dunnage air bags. To ensure that you have proper securement, follow these basic steps.

Quality Focus

Bulk-Pack puts a high focus on inspection and testing of our inflatable dunnage air bags. A single knick, pin hole, or faulty valve is unacceptable thus we put forth a strong quality program to make sure that the product meets and exceeds industry standards. We test a minimum of 16% of all air bags made, check pressure after 2 minutes, then again after 20 minutes to make sure it passes the standard we use.

If any failures are found, we double the amount of bags checked. If any more are found out of that order, we check 100% for that day's production.

We also check all inbound materials for burst test requirements to make sure all products meet and exceed the product's requirement.

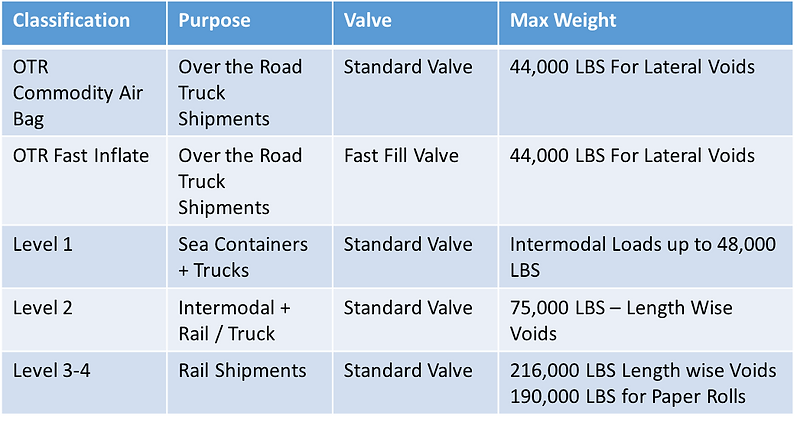

Our Product Range

Bulk-Pack has the ability to manufacture the Polywoven Dunnage Air Bags. In case of paper dunnage air bags, we will be glad to offer your Paper Dunnage Air Bags in stead.

Useful Handling and Load Configuration Documents

The American Association of Rail Roads (AAR) has done extensive research on the proper loading of products depending on the application.

Click the Link Below to our "Learn More" page and you will find useful links that may fit your needs.